All Categories

Featured

Table of Contents

- – Remodeling Rv Eastvale, CA

- – OCRV Center

- – Replace Rv Flooring Eastvale, CA

- – Rv Couch Bed Eastvale, CA

- – Rv Restoration Companies Eastvale, CA

- – Awning Installation Eastvale, CA

- – Rv Chairs Eastvale, CA

- – Rv Sofa Beds Eastvale, CA

- – Rv Carpet Replacement Eastvale, CA

- – Awnings For Trailers Eastvale, CA

- – Rv Replacement Furniture Eastvale, CA

- – Motorhome Carpets Eastvale, CA

- – OCRV Center

Remodeling Rv Eastvale, CA

Similar to the home windows in your automobile or home, there are a few various kinds. Maybe you want a window in your door so that you can let in the sunlight? Inspect! The Motor Home Entry Door Obscure Glass Home window is best for that, with the addition that you can have your privacy while still allowing the light.

And if you want your home windows to be tinted, we can aid you there. I'm sure you're aware of all that a home window can do.

Without the windows to allow in the light to inform you whether it's night or day, you can get all kinds of blended, perhaps even miss out on a large occasion. Or imagine you're having a cookout with your family and you run inside to obtain some more hot pets. Without a window, you wouldn't be able to see that your daughter is getting extremely close to the fire and no person else has discovered yet.

Replace Rv Flooring Eastvale, CA

The sun is a great decorating tool to utilize, lighting up area and visually increasing it. All the most effective designers understand just how much of an effect lighting can have. Whether you're using it to draw attention to an incredible item of artwork or include heat to an entire area, illumination makes all the difference in a space.

If you have older windows that require changing, the procedure for setting up the new home windows isn't as simple as it looks. You need to remove the inner structure of the old home window by removing the screws. You require to remove the external frame of the window by pushing it out of the window area.

Next, remove any one of the old sealers from the location with a putty blade. Once that is done, tidy the location with an ideal cleanser. When your location is tidy and devoid of particles, inspect the architectural components of the window opening. If there is anything that requires repaired (rusted staples, as an example), make certain you repair them before mounting the brand-new window.

Once more, see to it you are utilizing the help of another person to keep whatever straight and also and avoid the home window from falling. When the external framework and the glass framework remain in place, protect them by placing and safeguarding the internal framework on the inside of the window area.

Rv Couch Bed Eastvale, CA

Our team believe in providing the greatest worth, quality, and selection (Rv Restoration Companies Eastvale). Plus, we desire you to appreciate your acquisition! In the event you wish to send out an item back to us, you may return most unused things for a reimbursement or exchange, minus delivery, within 90 days from the day of purchase unless noted below under exemptions and exemptions

For internet orders, please get in touch with our customer care group(1-888-626-7576) to ensure your return or exchange is documented and any kind of prospective questions have been answered. For the most part, a return authorization will certainly be supplied, and, in every situation, we'll start to maintain an eye out for your return. For web orders returned in-store, please take the item in initial product packaging, along with the invoice to any Outdoor camping Globe retail locations for a reimbursement or exchange.

Rv Restoration Companies Eastvale, CA

Refunds for internet orders released in-store are able to be reimbursed to a GIFT CARD or MAILED CHECK ONLY; some exclusions might apply. For retail acquisitions returned with a receipt, please return the extra and unopened thing, with the original sales invoice, for a full reimbursement or exchange. All returns with a present receipt will obtain an installment plan for the amount of the thing at the time of purchase.

Appropriate ID will be required in the kind of a legitimate, state-issued vehicle driver's certificate or state ID card. We reserve the right to restrict or reject returns without an invoice. Great Sam Participants that have actually kept a constant active subscription condition might return any kind of extra and unopened item, acquired on Feb.

When it comes to RV travel, having the ideal windows can make all the difference. Whether you're seeking much better insulation, boosted air flow, or simply a far better view, there are a few key factors to take into consideration when picking the most effective motor home home window for your car. Below are five tips to help you make a notified decision and enjoy your journeys to the maximum.

Awning Installation Eastvale, CA

Set windows are fixed and can not be opened, while sliding home windows can be opened horizontally or up and down. Awning home windows are pivoted at the top and open external, offering exceptional ventilation.

Search for windows that are made from tempered glass, which is stronger and much more resistant to breakage than regular glass. In addition, the framework should be made from strong materials like light weight aluminum or vinyl, and ought to be created to stop leakages and drafts. Buying a premium RV window will certainly make sure that it lasts for lots of years and offers reputable efficiency on your journeys.

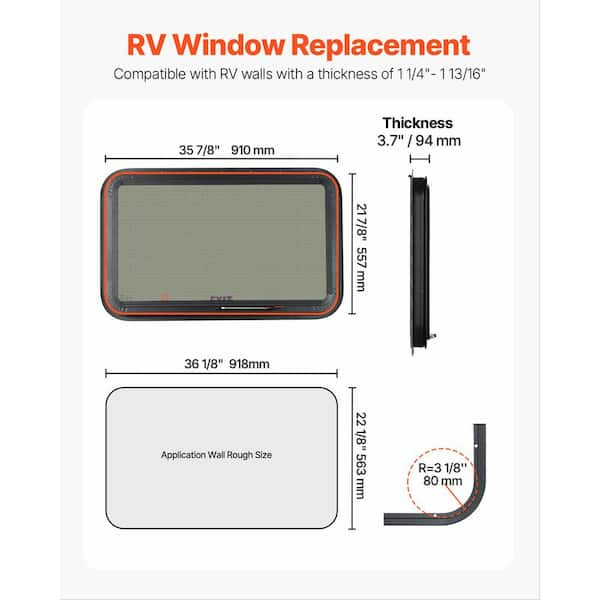

The home window needs to fit snugly right into the room given, without any type of voids or spaces that can enable drafts or leakages. Procedure the opening thoroughly and choose a home window that matches the dimensions. In addition, think about the form of the home window and exactly how it will certainly fit with the overall design of your RV.

Rv Chairs Eastvale, CA

Your recreational vehicle's windows are the secret to delightful outdoor camping, letting you see all the sights of the road and your locations. If you're driving a motorhome, the windscreen is one of the most vital window on the whole recreational vehicle. Despite which sort of RV you own, your home windows are a vital part of outdoor camping.

Older Recreational vehicles were developed with less sophisticated home window systems, so there is wear and tear that may be noticeable., however certain problems like haze, scrapes, or problems with the covering of the window might suggest it's time to replace your RV windows.

There are cracks, deep scratches, or chips in the windows. The windows are no longer snugly secured. Wind or water goes into the rig from around the windows, even when the home windows are closed. Your home windows aren't properly insulated. Your home windows rattle when the RV is in movement. Wondering if it's time for a motor home home window replacement? Get in touch with your regional Lazydays RV dealer to find out more about our home window replacement and recreational vehicle glass repair solutions! When replacing your motor home home windows, you're able to choose the right window for your RV and your demands.

Rv Sofa Beds Eastvale, CA

There are also options such as clear glass, pebbled windows, and tinted motor home windows. Your design, protection, and home window make use of demands will assist determine which sort of motor home home window you select. Your recreational vehicle's window structures integrate the exterior and interior elements of your RV, and they need to be properly mounted to make sure that the sidewall's seal stays water tight.

The finest means to ensure that your RV window substitutes are mounted effectively is to leave it to the specialists. Our RV service experts can replace any windows and glass on your recreational vehicle, including the windshield, side home windows, and also the a lot more intricate recreational vehicle door window substitute. Door home windows, if not mounted correctly, can rattle when you're making use of the motor home door, so leave that repair work to our professionals at Lazydays motor home.

Rv Carpet Replacement Eastvale, CA

These windows open external with a crank mechanism, enabling for ventilation while minimizing rainfall access. Commonly bigger home windows that do not open, offering unhampered sights and light if furnished.

Supplies a watertight seal around the home window. While Recreational vehicle windows differ from domestic home windows, they require routine interest and upkeep to prevent issues like water leakages.

Awnings For Trailers Eastvale, CA

To ensure the long life and efficiency of your RV home windows, consider the adhering to ideas: Examine the location where the home window meets the wall for any spaces or voids. In extreme cases, you might need to eliminate the window and reinstall it using putty or foam seal.

We motivate customers to verify the contents and seek advice from their supplier or Keystone recreational vehicle for the most existing information. If you have any inquiries or call for more clarification, please do not think twice to contact your supplier or reach out to Keystone recreational vehicle directly.

For those of you who are a lot more visual, you'll value our detailed tutorial video clip, embedded below. If you prefer the composed word, the steps are laid additionally down the web page. Or delight in both! These are the tools we required for our camper home window substitute. Depending upon your motor home, you may or may not require all of these devices for your task.

No matter where you acquire your new RV window, you'll need to offer accurate dimensions. Allow's damage down our procedure for gauging a RV home window for substitute.

Rv Replacement Furniture Eastvale, CA

Don't place any type of external stress on the home window while taking your dimensions, or it might come loose and fall. For additional safety, you might wish to have a helper on a ladder outside, holding the home window in location while you measure. Very carefully remove the framework of your old window to make sure that you can gauge the opening (NOT the window itself).

For our rectangle-shaped window, we required to take only 4 measurements. Likewise, understand that we're gauging the opening itself. Making use of a determining tape, take mindful note of the width and height of the opening. It's a good concept to take dimensions at several points so you have an idea of how cleanly the window opening was cut.

Motorhome Carpets Eastvale, CA

Next, gauge the density of the wall (depth of the home window), from the outside wall surface area to the indoor wall surface area. For this dimension, use your ruler (with dimensions that run completely throughout). Place the leader right into the wall until it touches the beyond the home window structure.

Dimensions of the old window and the home window opening are frequently different. As a matter of fact, they can vary as much as half an inch on the sides, top, and bottom. Window makers make use of filler strips to maintain the window degree and snug. This is why it's so essential to measure the opening and not the original window itself.

Procedure two times, cut as soon as? Take your time to get a precise measurement, and verify it by determining a 2nd time. Specific measurements are necessary to RV home window substitute. You do not intend to loosely measure and assemble or down. Constantly measure to the local 1/16th of an inch. Take a close look at your tape measure and be certain you understand which are the 1/16th-inch dimensions.

OCRV Center

Address: 23281 La Palma Ave Yorba Linda, CA 92887Phone: (714) 909-1444

Email: art@ocrvcenter.com

OCRV Center

The window suppliers are the finest authorities on installing their products. The manufacturer of your new RV window has most likely included handy standards or suggestions to make the installation less complicated. These kinds of instructions are typically included on manufacturers' websites also. If your brand-new home window featured directions in the package, make certain to keep those useful, as they may have described step-by-step directions in a consisted of pamphlet.

Rv Replacement Furniture Eastvale, CARv Carpet Installation Eastvale, CA

Motorhome Carpets Eastvale, CA

Rv Floor Replacement Eastvale, CA

Rv Carpet Installation Eastvale, CA

Rv Interior Furniture Eastvale, CA

Rv Upholstery Eastvale, CA

Motorhome Carpets Eastvale, CA

Replacement Rv Windows Eastvale, CA

Rv Chairs Eastvale, CA

Rv Sofa Beds Eastvale, CA

Rv Replacement Furniture Eastvale, CA

Rv Dinette Table Eastvale, CA

Rv Refrigerator Replacement Eastvale, CA

Remodeling Rv Eastvale, CA

Rv Restoration Companies Eastvale, CA

Replacement Windows For Campers Eastvale, CA

Rv Chairs Eastvale, CA

Rv Couch Eastvale, CA

Rv Interior Remodel Eastvale, CA

Rv Dinette Table Eastvale, CA

Rv Sofa Beds Eastvale, CA

Rv Restoration Companies Eastvale, CA

Rv Interior Furniture Eastvale, CA

Rv Dinette Booth Eastvale, CA

Replacement Rv Windows Eastvale, CA

Rv Microwave Replacement Eastvale, CA

Rv Refrigerator Replacement Eastvale, CA

Rv Sofa Beds Eastvale, CA

Rv Replacement Awnings Eastvale, CA

Rv Couch Eastvale, CA

Rv Dinette Table Eastvale, CA

Rv Refrigerator Replacement Eastvale, CA

Rv Interior Furniture Eastvale, CA

Rv Restoration Companies Eastvale, CA

Rv Dining Table Eastvale, CA

Rv Dinette Table Eastvale, CA

Replace Rv Flooring Eastvale, CA

Rv Interior Remodel Eastvale, CA

Remodeling Rv Eastvale, CA

Remodeling Rv Eastvale, CA

Rv Restoration Companies Eastvale, CA

Replace Rv Flooring Eastvale, CA

Rv Microwave Replacement Eastvale, CA

Rv Dinette Booth Eastvale, CA

Rv Dining Table Eastvale, CA

Replace Rv Flooring Eastvale, CA

Rv Carpet Replacement Eastvale, CA

Rv Replacement Furniture Eastvale, CA

Rv Carpet Installation Eastvale, CA

Rv Dining Table Eastvale, CA

Rv Sofa Sleeper Eastvale, CA

Awnings For Rv Eastvale, CA

Rv Chairs Eastvale, CA

Rv Couch Eastvale, CA

Remodeling Rv Eastvale, CA

Motorhome Carpets Eastvale, CA

Rv Sofas Eastvale, CA

Rv Upholstery Eastvale, CA

Rv Restoration Companies Eastvale, CA

Rv Chairs Eastvale, CA

Replace Rv Flooring Eastvale, CA

Rv Refrigerator Replacement Eastvale, CA

Rv Dining Table Eastvale, CA

Rv Dining Table Eastvale, CA

Replacement Rv Refrigerator Eastvale, CA

Rv Carpet Replacement Eastvale, CA

Rv Replacement Furniture Eastvale, CA

Awning Installation Eastvale, CA

Rv Dinette Table Eastvale, CA

Rv Chairs Eastvale, CA

Rv Restoration Companies Eastvale, CA

Rv Dinette Booth Eastvale, CA

Replacement Windows For Campers Eastvale, CA

Rv Interior Remodel Eastvale, CA

Rv Couch Bed Eastvale, CA

Awnings For Rv Eastvale, CA

Awnings For Trailers Eastvale, CA

Close By Seo Package Eastvale, CA

Finding A Local Seo Expert Eastvale, CA

OCRV Center

Table of Contents

- – Remodeling Rv Eastvale, CA

- – OCRV Center

- – Replace Rv Flooring Eastvale, CA

- – Rv Couch Bed Eastvale, CA

- – Rv Restoration Companies Eastvale, CA

- – Awning Installation Eastvale, CA

- – Rv Chairs Eastvale, CA

- – Rv Sofa Beds Eastvale, CA

- – Rv Carpet Replacement Eastvale, CA

- – Awnings For Trailers Eastvale, CA

- – Rv Replacement Furniture Eastvale, CA

- – Motorhome Carpets Eastvale, CA

- – OCRV Center

Latest Posts

Water Heater Repair Service Sabre Springs San Diego

Sorrento Valley San Diego Residential Plumbing Companies Near Me

Plumber Repairs Near Me Sabre Springs San Diego

More

Latest Posts

Water Heater Repair Service Sabre Springs San Diego

Sorrento Valley San Diego Residential Plumbing Companies Near Me

Plumber Repairs Near Me Sabre Springs San Diego